Joel and his Pro-Am K24 BRZ pt 1.

“Who the hell is this Joel bloke and how has he built this car in his back shed??!!??!?”

I started following Joel’s build on instagram (@brzdiy) about 12 months ago and was in awe of the project Joel had taken on. Not only was it complex given he’s taken a production chassis and changed all the factory suspension pickups but the fact that Joel has done all the work himself in his back shed in suburban Sydney hurts my brain a little, I won’t lie.

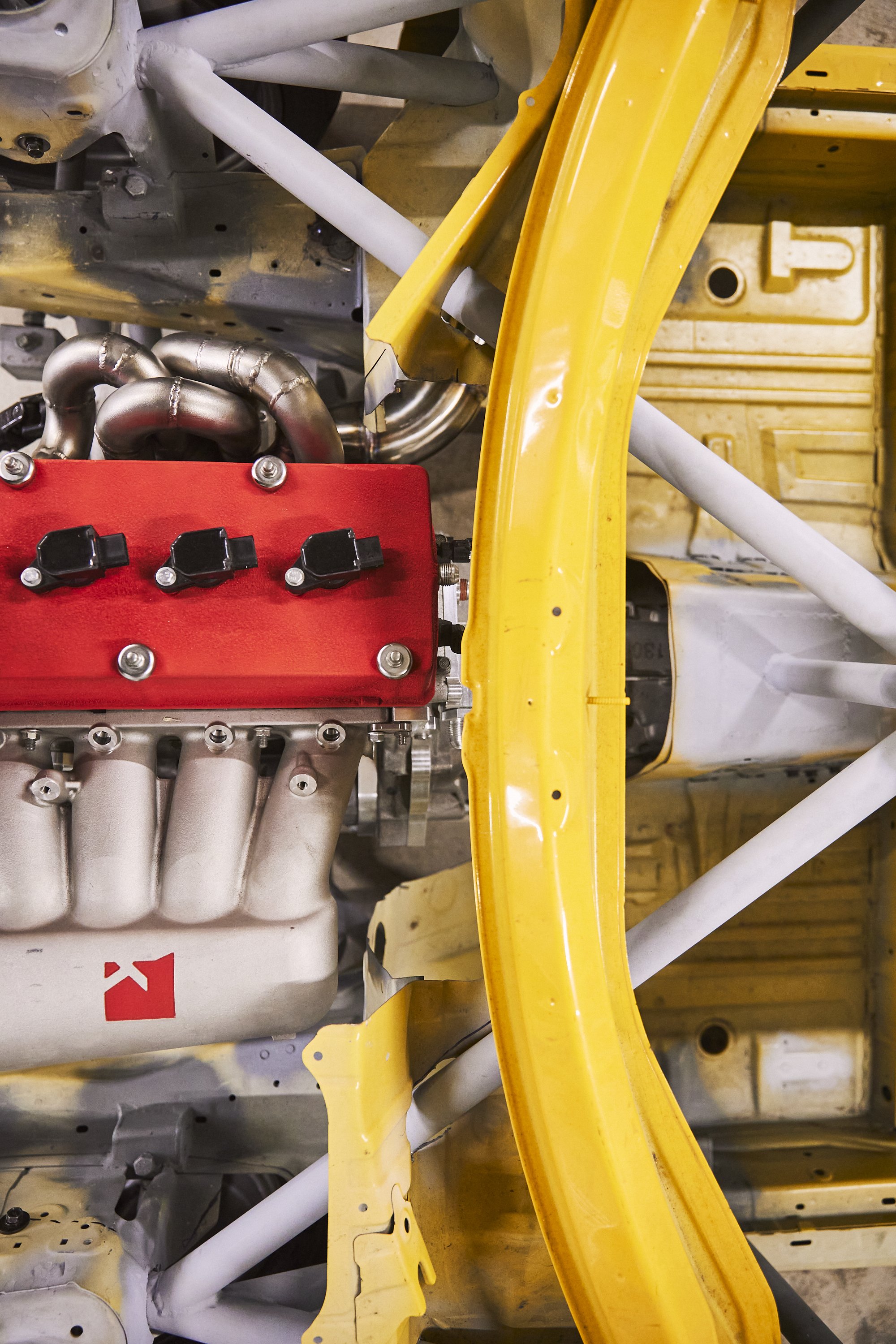

Walking down Joels driveway I was abit confused. The long driveway lead me to a two wide standalone shed - “surely this isn’t it” I thought to myself. I peered into the open side door and seeing the stripey yellow BRZ for the first time was like meeting an online friend in person. Slightly odd! glad I wasn’t being catfished here though as the BRZ looked just as cool in the flesh as it did online!

I figured the best way to tackle a long term feature like this one is in parts so lets start here, part one: A quick introduction to Joel and his BRZ.

What’s your background in motorsport?

I have about 10 years of racing experience at club level in my WRX. Mostly Motorkhana on both wet and dry skidpan and Khanacross on gravel. I also did a couple of seasons of Supersprints all with the Impreza WRX club of NSW.

What’s your background in car building?

My first car was a 1964 EH Holden and at the age of 19 I started a ground up restoration (resto-mod) of this car that took me about 2 years to complete. This was pre-internet so I had to figure things out for myself. At the time I was an apprentice in a sign manufacturing company where I was mostly focused on spray painting the signs and some very basic fabrication so I used these skills to help build the car.

The next project was my MY05 WRX which was just a daily driver that ended up getting heavily modified as I got more and more addicted to motorsport. I still own and compete in this car which is mostly a mix of aftermarket and genuine bolt-on performance parts with a heavy emphasis on weight reduction.

My last project car before the BRZ was a sleeper build with an engine swap in a MY02 Subaru Outback. I purchased the car cheap with a blown head gasket and a JDM MY03 XT Forester turbo engine was swapped in with a stealth water to air intercooler system, the car looked completely original from the outside.

Do you have any trade qualifications?

I completed the auto body painting course at TAFE as part of my apprenticeship as it was more relevant than the Signwriting course at the time. After I completed my apprenticeship I did my HSC at TAFE in one year then spent 3 years at University getting a Chemistry degree. I now work as an Instrument Scientist in a materials science and engineering research facility.

What’s the end goal for the car?

The car is being built to WTAC Pro-am rules on less than a Clubsprint budget. I don’t know if I will ever enter WTAC but I wanted to follow some rules to ensure the car has more value if I ever did choose to sell it.

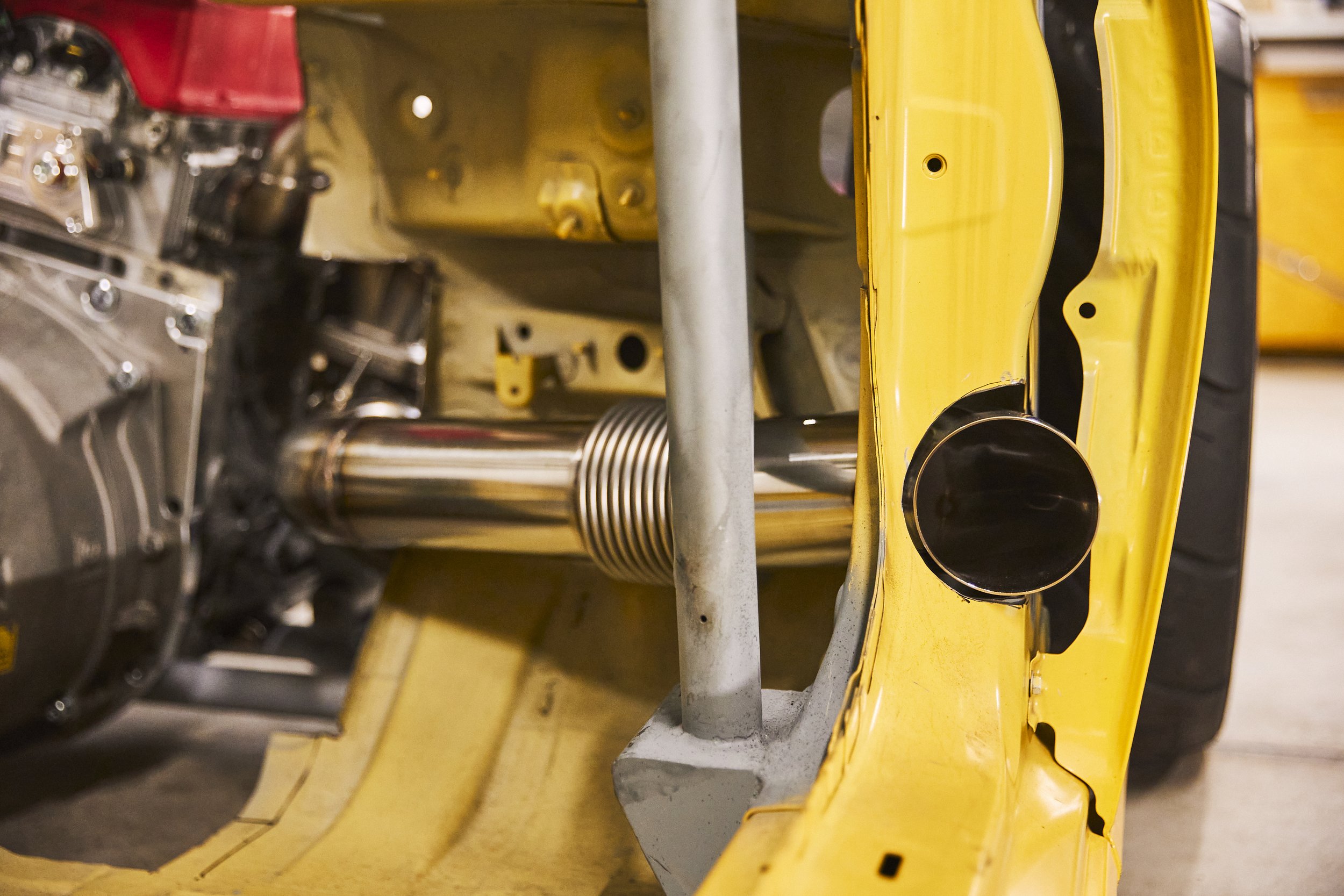

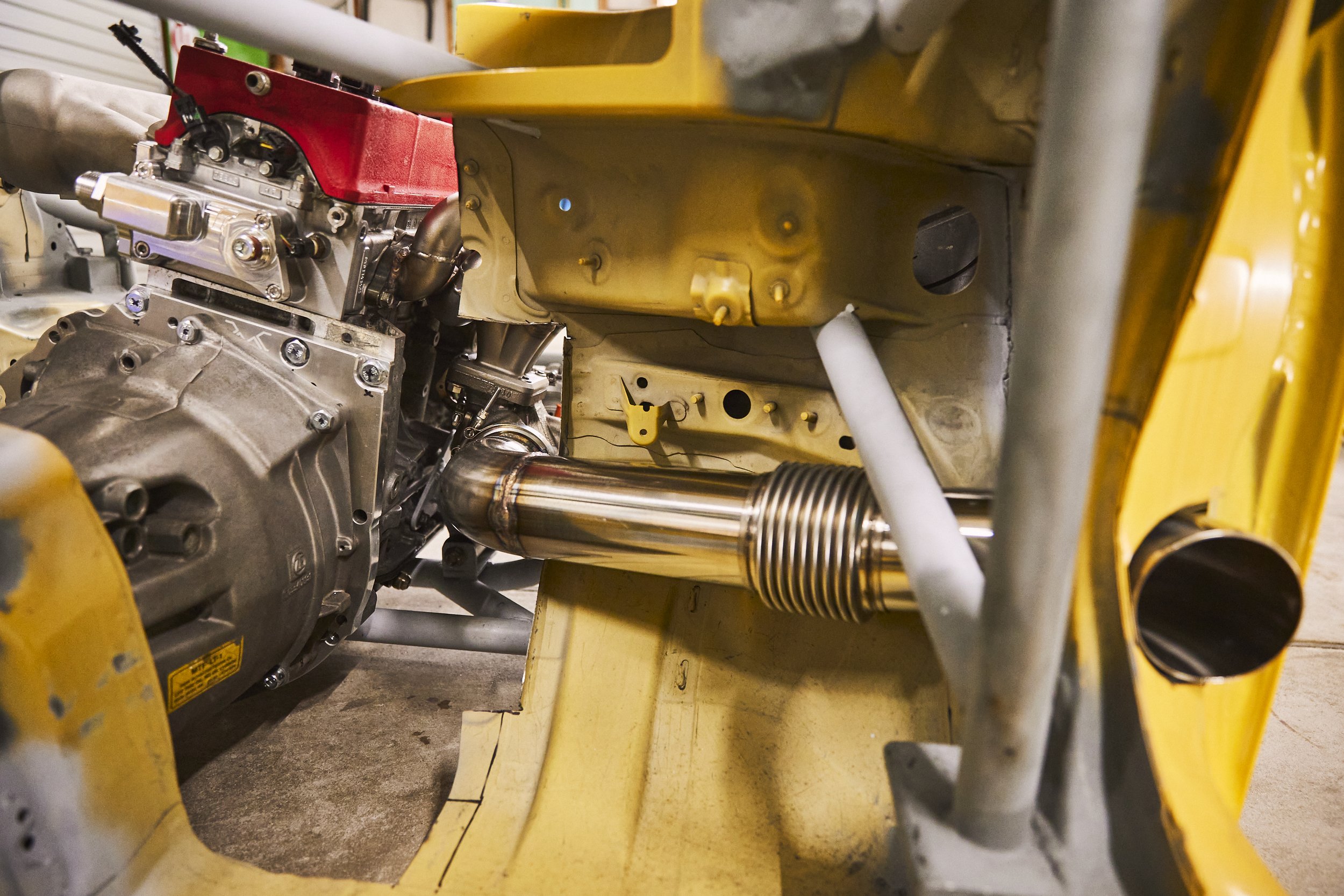

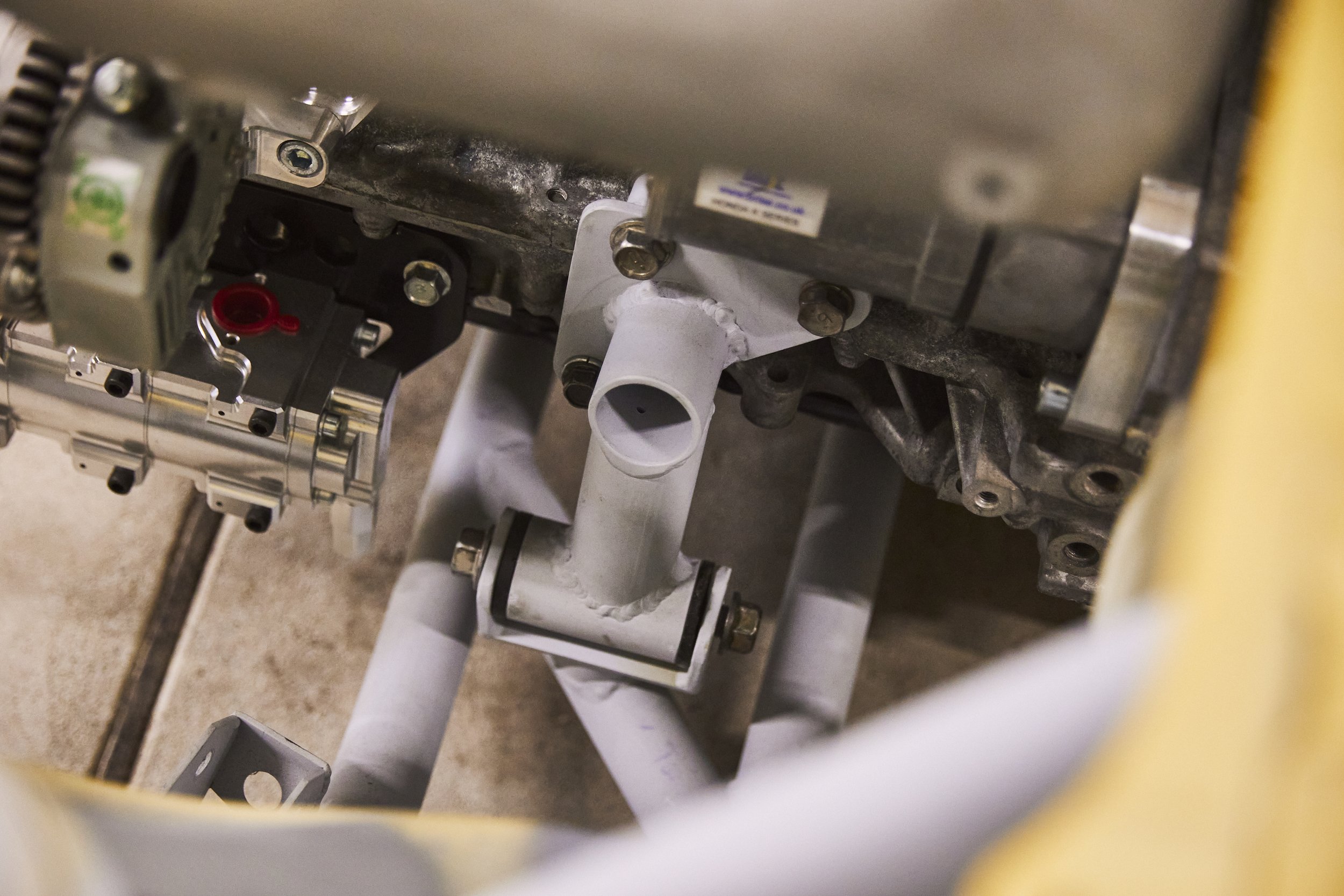

The Pro class rules were the only rules that allowed me the complete freedom to bring some of my ideas into reality. I like to build and create things just as much as I like to drive them. My basic plan is to install lots of sensors, gather lots of data and keep tweaking things to see how fast it can go on a limited budget. I have built an incredible amount of adjustability into the chassis.

How did you land on using a BRZ as a base?

Initially I thought about converting my WRX to a time attack car but I really liked how well it was set up for Motorkhanas and Khanacross, I feel the WRX is better suited to this kind of racing, especially on gravel, so I decided to start a fresh build.

Being a long term member of the WRX club I have many friends in the club and really enjoy attending and competing at their events. So it had to be a Subaru as they do allow you to compete in any type of Subaru, it’s not just for WRX owners. The BRZ was the obvious choice for a time attack car with its low drag body shape, light weight shell and I felt the RWD platform would simplify things and help the overall weight and balance.

Was it always your intention to buy a shell?

I was bidding on written off cars at the auctions for a while but the prices were going too high considering I was not going to use much more than the shell for what I had planned.

What is the brief history of this shell?

The shell was originally imported into the country a couple of years before I bought it. The importer was not able to sell it initially and it ended up sitting in a farm paddock under some tarps for a while. I remembered seeing the original for sale advertisement so I contacted them to see if they could get another one in from Japan. Well, as it turned out they still had the original one so I made a family holiday of it and we drove all the way from Sydney to the Sunshine Coast to pick it up.

All I was told at the time was the shell was used on the production line in Japan to set up the robots for the automated painting process.

Are you keeping it yellow?

I really like the yellow colour but at this stage I’m not sure if I will keep the same look it has now or just keep some of the yellow. Most of the metal will be replaced with composite panels eventually so it will need to be painted again or possibly wrapped.

Why K24?

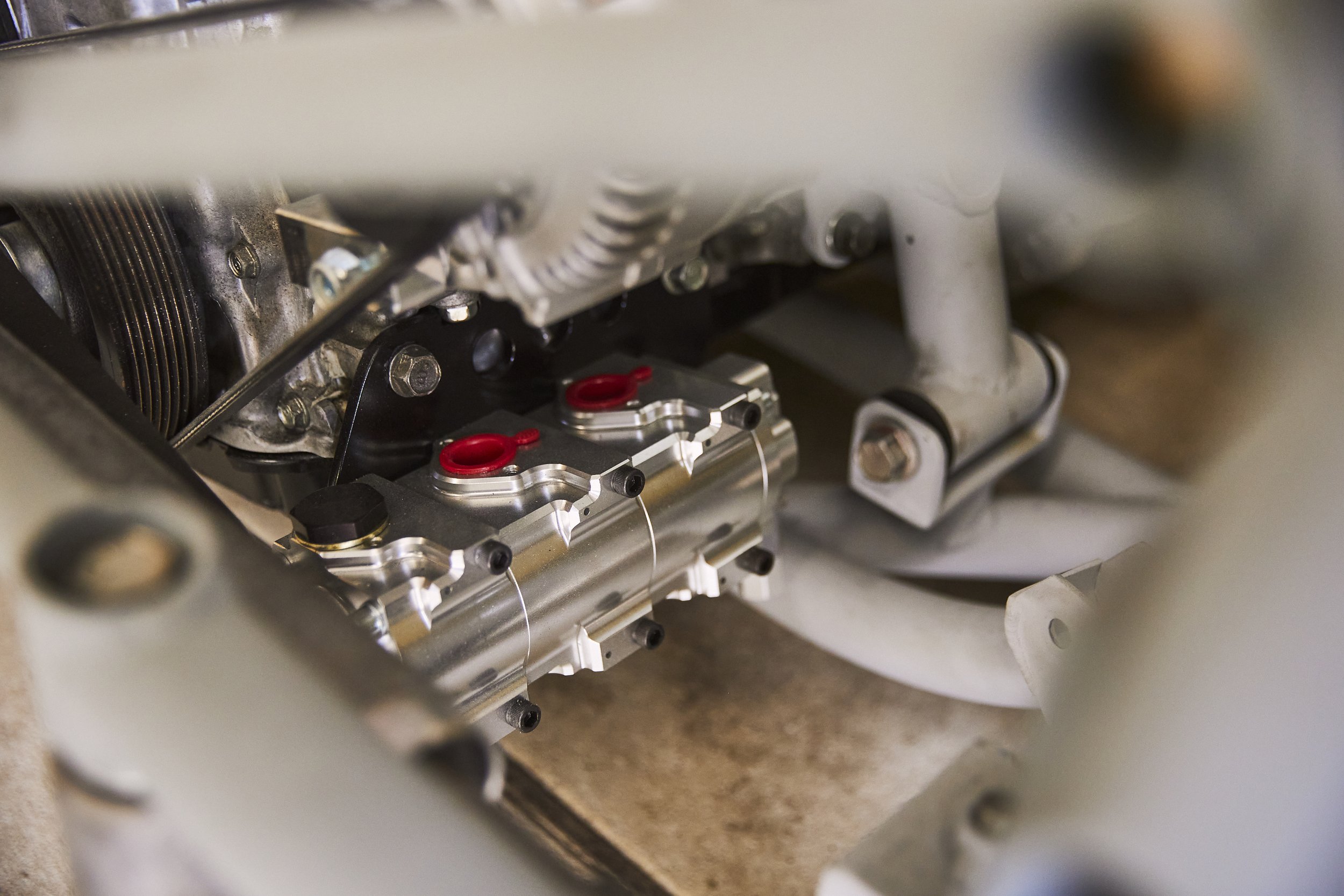

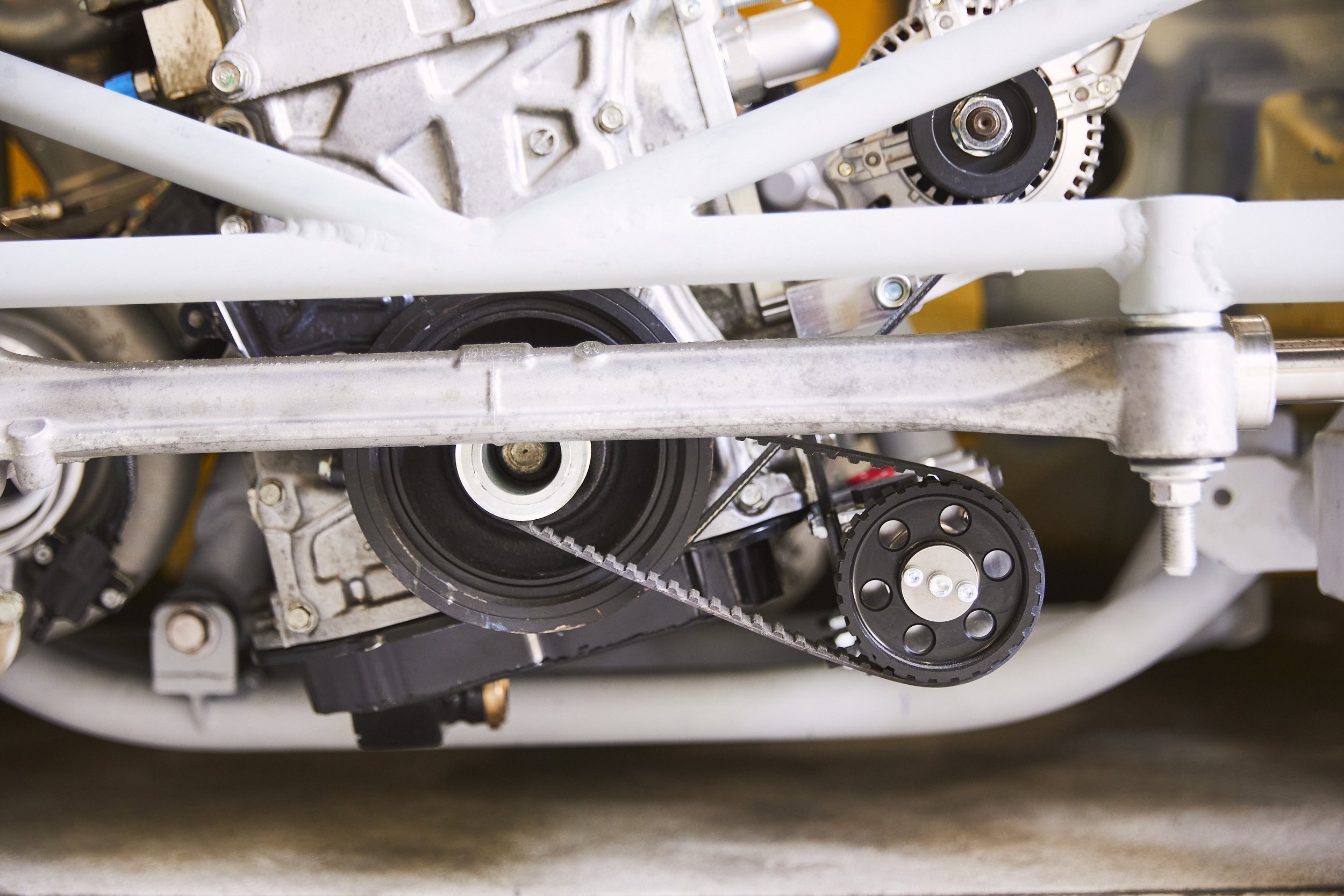

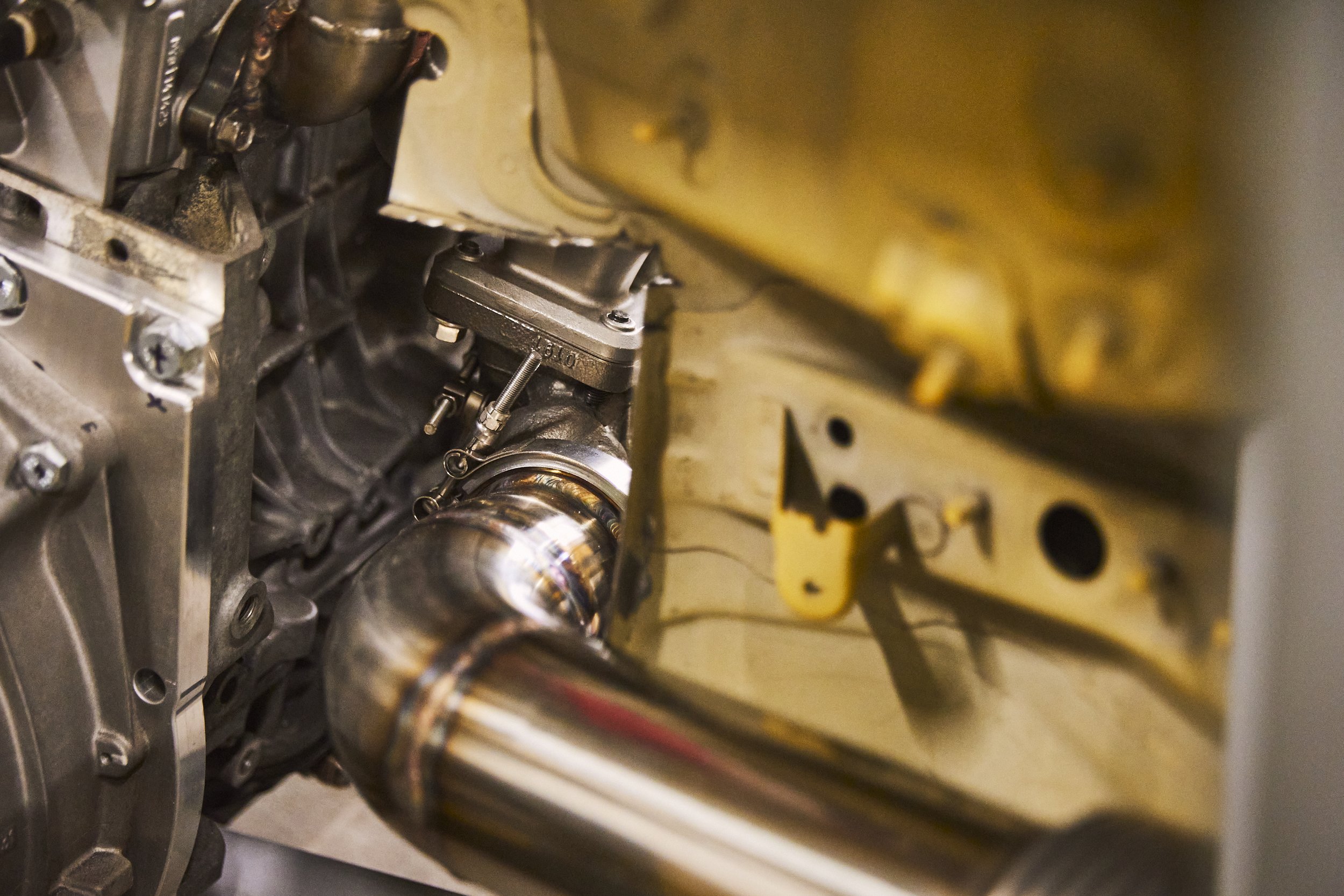

Originally I wanted to run an EJ207 as I have some experience with Subaru but they are expensive motors to buy and build. When I started looking at some other potential options the Honda K24 really stood out as a great bang for buck engine. Specifically the K24A3 found in the Australian delivered Honda Accord Euro as they are a high performance version of the K24 with the VTEC on both the intake and exhaust cams. With the Accord being such a common family car in Australia these engines are readily available and very inexpensive to buy. The K24 is capable of moving a lot of air and can produce high power in both naturally aspirated and forced induction applications.

So that just about wraps up part 1 with Joel and his BRZ. I already know he’s made some great progress since I last visited so I would love to catch up again sometime in the future and bring the progress to you all! If you have any questions be sure to flick me an email and I will include it in part 2!